It has been exactly 170 years since the birth of the world’s first refinery in 1853.

As an ancient but constantly evolving and innovative foundational industry, the refining industry has gone through a transformation process from primarily using lighting oil and automotive/aviation fuel, to currently being dominated by chemical products in the integrated refining and chemical industry. During this period, different processes such as atmospheric and vacuum distillation, catalytic cracking, delayed coking, and hydrocracking not only innovated and iterated on their own, but also gave birth to a new revolution in automation and digital technology from computer control to PLC, DCS, and now integrated refining and chemical plants.

In fact, from refining and chemical industry to typical process industries such as electricity, steel, building materials, nuclear power, medicine, and even emerging green hydrogen, green ammonia, electrolytic aluminum, etc., the process automation and digital innovation around processes are undergoing rapid changes. Among them, refining represents complex process industries. Let’s start from the refining industry and take a look at innovative and integrated solutions for the entire process industry.

The ultimate pursuit of “stability, longevity, and excellence”

In the refining industry, as the demand for refined oil slows down, “controlling refining and increasing production”, producing more chemical products, and improving processing depth have become the new normal for the development of the global refining and chemical integration model. It is also the main strategic choice for refining enterprises to optimize resource allocation, reduce production costs, and increase added value today. This mode not only means the tightly integrated process design of mutual supply of raw materials and products, closed-loop utilization of energy and common use of public facilities, but also brings about the complexity of the process and the large-scale and large-scale devices.

In order to continuously pursue the ultimate goal of “safe production, stable product quality, long-term operation of equipment, full load production, and optimized operation” for the operation of large-scale integrated process equipment, refining enterprises urgently need to reform a series of links such as automation engineering design and delivery, instrumentation, control, operation, maintenance, equipment management, and public works. Among them, the most core control and safety systems are the control and safety systems, The transformation challenges that need to be addressed include:

(1) Higher security: In order to ensure the safety of large-scale and complex integrated production processes, DCS and SIS systems need to have higher security functions, such as redundant design, safety interlocking, fault tolerance, and fault safety mechanisms, and even the ability to cope with the information security risks brought by an increasing number of IT applications.

(2) Stronger stability: Due to the operational fluctuations of large-scale integrated devices, DCS and SIS systems need to undergo rigorous testing and verification from system design concepts to network communication, software to physical hardware to ensure their stability and reliability under various working conditions.

(3) Longer service life: In order to achieve long-term operation, DCS and SIS systems need to fully consider the reliability of the system in the design and implementation process, such as adopting redundant design, modular structure, excellent equipment alarm management, and scientific operation and maintenance methods based on big data.

(4) Higher device load rate: The concept of “stable, long-term, and optimal” emphasizes full load operation. For integrated refining processes, DCS systems need high-performance controllers and servers to ensure real-time performance and response speed.

(5) Better optimization of operation: Large integrated refining units are usually composed of multiple process units, and the strong coupling and nonlinear characteristics between various control variables increase the complexity and difficulty of operation. However, there may be mutual constraints between multiple objectives that need to be optimized, such as maximizing production, minimizing energy consumption, and maximizing profits. The requirement for “edge clamping operation” is higher.

In addition, in order to save resources and energy, the optimization process should also strive to meet strict low-carbon environmental protection requirements. If the power automation and control system can be well integrated, it can better carry out energy-saving optimization and monitor and avoid faults caused by the power supply system.

Accumulation and thin development, a complete integrated process solution

Schneider Electric is based on an open EcoStruxure ™️ Architecture and platform provide comprehensive process automation and digital solutions for users in various process industries such as refining, power, food, pharmaceuticals, green hydrogen and green ammonia, mainly covering EcoStruxure Foxboro process instruments, EcoStruxure Foxboro DCS distributed control system, EcoStruxure Tricon CX safety instrument system solution, EcoStruxure consulting software, and AVEVA full lifecycle solution, To promote the industry towards a more open, efficient, resilient, sustainable, and people-oriented future while meeting the operational goals of ensuring stability, growth, and excellence in the process industry.

(1) Innovative advantages of EcoStruxure Foxboro DCS system

Foxboro DCS, which was born in 1987, has undergone more than 30 years of iteration and practical application verification. Its hardware, software and communication network have always been downward compatible around the design idea of “long-life structure”, and constantly improved with new technologies. Its innovative characteristics are mainly reflected in the openness, reliability and technological progressiveness of the system.

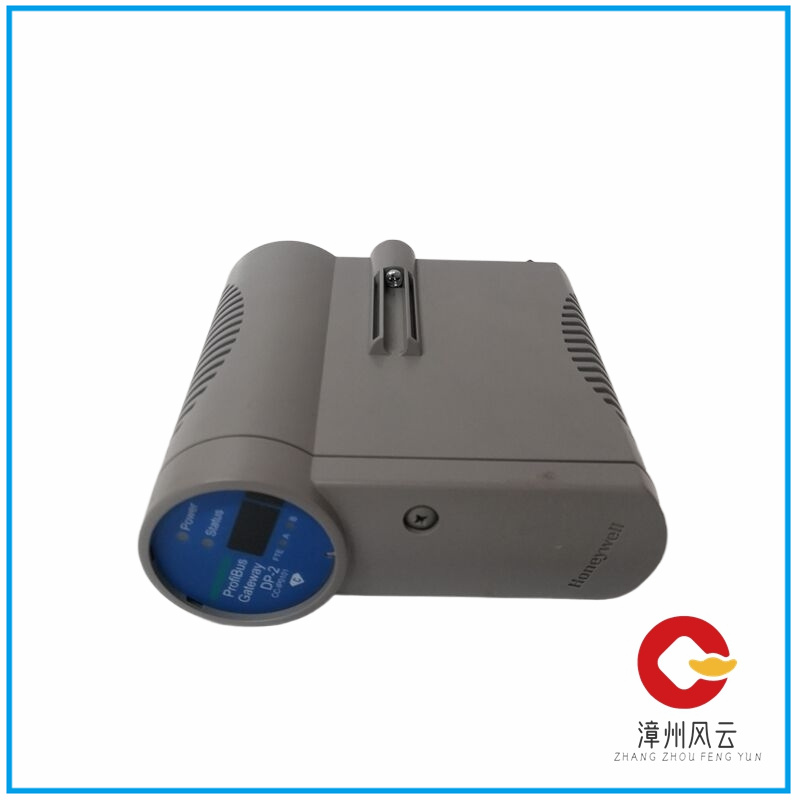

Whether it is the support of the core controller for various process instrument bus protocols, Ethernet bus, serial bus, or even the IEC61850 distribution system connection protocol, or the upward connection to the production pipeline network based on open protocols, or even cloud based engineering development, FAT testing, SAT testing, the openness of EcoStruxure Foxboro DCS can be described as keeping up with the times.

In terms of reliability, EcoStruxure Foxboro DCS provides multiple redundant communication networks, redundant power supply systems, mutually backup operating stations, redundant fault-tolerant control processors, and network security design from individual components to the entire system, ensuring continuous and normal operation of the system.

The EcoStruxure Foxboro DCS controller has complex computing capabilities such as self-tuning and multivariable self-tuning. The software supports virtualization technology, provides dynamic picture HMI, and provides remote access to the system through remote system management and system diagnosis software packages, as well as the in-depth optimization capabilities brought by AVEVA APC advanced process control software, all of which well reflect the progressiveness of the system.

25

1 月

24

0

comment

2024年1月25日

Categories: