To ensure the normal operation of the DCS operating system, it is necessary to ensure its regular maintenance in order to meet your work needs. How to perform daily maintenance on the DCS operating system?

1. Daily inspection of DCS operating system

1) Strengthen the training of system maintenance personnel. Enable maintenance personnel to operate and be proficient in maintenance.

2) Conduct daily checks on the operation of the system and keep records to identify the regularity of system failures. For targeted maintenance.

3) Check the temperature and humidity changes of the system daily to ensure they meet the system’s operational requirements.

4) Check the operation of the backup power supply and DC power supply for system power supply voltage.

5) Check the operating status of the input and output card indicator lights.

6) Check the operational status of the communication network. Check if the redundancy status is normal.

7) Check the alarm interlock record. Is there any abnormal record, etc

2. Issues to be noted during the maintenance process of DCS operating system

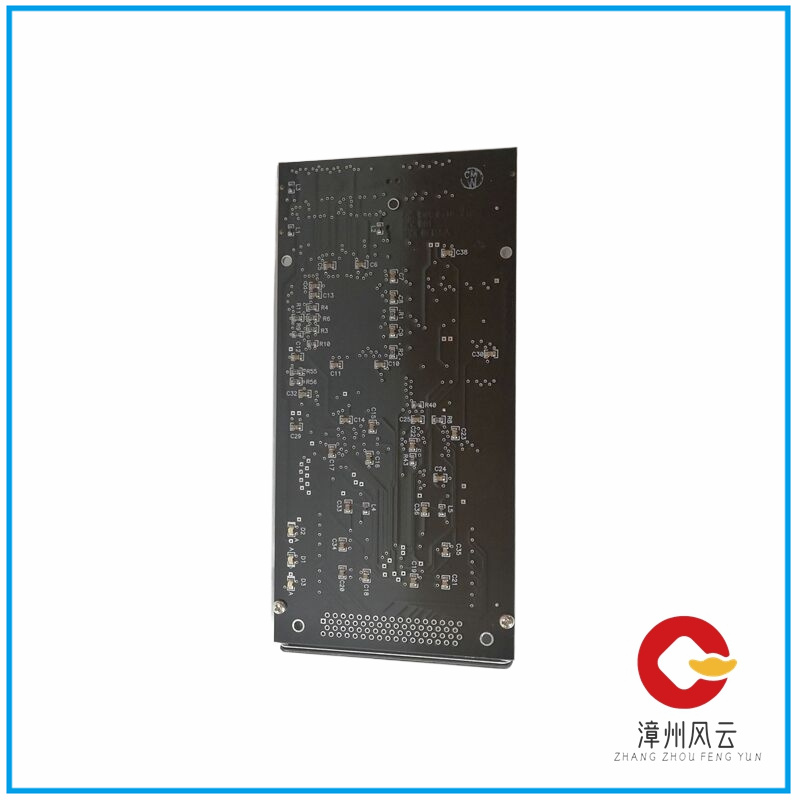

When maintaining the DCS operating system, if it comes into contact with the integrated circuits and component solder joints on the system components, it may cause electrostatic damage. Static damage includes card damage, decreased performance, and shortened service life. To avoid damage caused by static electricity during maintenance, the following points should be noted:

1) Before removing the card, anti-static measures should be taken. If wearing a well grounded anti-static wrist or conducting human discharge.

2) The replaced or spare card components should be installed in an anti-static sleeve, and it is strictly prohibited to place them randomly. Do not touch the solder joints artificially, and do not touch the components on the card components.

3) After replacing the card, it should be confirmed that its attribute settings are consistent with the original ones. Power distribution of card entry components, jumper addresses, redundancy settings, etc.

4) Daily maintenance should avoid randomly pulling cables or damaging the connections between cables and network cables, especially the cables, to avoid causing virtual knots and poor contact.

5) Take advantage of equipment overhaul opportunities to carry out planned comprehensive system maintenance. Power outage is required for comprehensive system maintenance. The steps for powering off the DCS operating system are:

(1) Each control station exits the monitoring interface and operating system in sequence, and turns off the power to the host and display.

(2) Turn off the power supply of the control station power box one by one

(3) Turn off the uninterruptible power switch

(4) Turn off the main power switch;

3. DCS operating system maintenance

After a power outage, the micro interior, control station chicken cage, and power box should be thoroughly cleaned of dust. Clean the dust screen of the control cabinet, etc.

Inspect the power supply lines, wiring terminals, safety barriers, etc. of the system to ensure normal and reliable wiring.

Conduct a comprehensive inspection of the system grounding wire to ensure its firmness and reliability. The grounding resistance meets the design requirements. Test the performance of the power supply to ensure that it meets the requirements for normal operation. Test and repair the insulation of the circuit, replace the cards that cannot be replaced during normal operation, and address any defects or deficiencies found during operation that cannot be addressed at that time. Restore various flags.

Inspect and verify on-site instruments. Comprehensive maintenance and repair of transmitters, regulating valves, etc. Replace damaged wires. Inspect and repair the air source of the regulator. Inspect and replace the gas supply pipeline. Clean the filter. Check the signal line to ensure reliable connection. The signal transmission is normal.

Conduct a comprehensive inspection of signal alarms and signal interlocks to ensure compliance with process requirements. Check and record the set parameters. Conduct simulation experiments on chain electricity.

In short, a comprehensive inspection and maintenance of the system is necessary. After comprehensive maintenance of the system. To power on according to requirements:

1) Final power supply. Control station power supply, operation station power supply. First, check the 220 volt AC and UPS output voltage of the control station, inspect the power box, and inspect the card distribution. The operation station is sequentially powered by a display and an industrial computer. The computer determines whether the system software files are correct after self checking. The hard disk file should remain unchanged. The card and network system indicator lights show no faults.

2) Perform redundancy testing on the card components,

3) Perform redundancy testing on network communication, and simulate the operation of the control system after normal system debugging. Check whether the output corresponds to the position of the regulating valve by giving signals from the operation station. Set the positive and negative effects according to the process requirements. Set the PID parameters according to the parameters before shutdown.